With Easter less than three months away, and product demand at its usual high for hot cross buns, chocolate and the like, we’re sharing some of our most popular equipment; guaranteed to improve the quality and efficiency of your product output this Easter period!

Chocolate Machines

Chocolate World Automatic Tempering Machine

Chocolate Worlds Tempering Machines are specifically designed to consistently temper your chocolate whilst simultaneously improving the quality. Equipped with a digital temperature display, a heated vibrating table and a pedal to dose the chocolate, this machine is available in 24kg, 40kg, 60kg and 80kg units. Thus, it is ideal for chocolatiers with a larger production demand. It also has an optional single-phase system available upon request, a fast melting and tempering cycle, and easy-to-move castors. You can learn more about the Chocolate World Automatic Tempering Machines here.

Pavoni MiniTemper Chocolate Tempering Machine

The Pavoni MiniTemper has been specifically designed as your perfect benchtop chocolate tempering solution with simple-to-use functionality and customisable programs. This bench-top chocolate machine allows you to maximise production without compromising on space and is perfect for any chocolatier with a small production capacity or if you’re just starting out. The tempering programs can be customised for your specific production and the chocolate can be maintained in its tempered state for several hours. It’s also simple to operate and clean with interchangeable bowls made of AISI 304 stainless steel and a transparent lid made of PET to maintain temperature. You can learn more about the Pavoni MiniTemper Chocolate Tempering Machine on our website here.

Chocolate World Tempering Wheels

The Wheelie Tempering machines by Chocolate World have been designed to efficiently melt and temper chocolate callets. Available in two models (a 14kg machine bench-top unit and a 30kg free-standing model), the Wheelie tempering machines are made to be low-investment machines, ideal for professional production. The 14kg unit has a digital thermostat and the 30kg unit is equipped with a vibrating table and is designed for a higher output of chocolate production. Nonetheless, both machines temper the chocolate to a smooth and velvety texture. You can learn more about the Chocolate World Tempering Wheels on our website here.

Chocolate World M1300 Enrober

The Enrobing Line by Chocolate World has been specifically designed to automate the traditional, time-consuming coating of confectionery and fillings with minimal wastage. Equipped with a double chocolate curtain, vibrating station, detailer and conveyor belt, this enrober dramatically increases product productivity and product consistency. The thickness of the chocolate coating can be adjusted by the vibrating system and blowing unit, and the conveyor belt speed can also be adjusted to suit each specific product and output. The enrober is simple to connect and operate, and easy to remove and store. Learn more about the M1300 Enrober on our website here.

Chocolate World Mini Moulding Line

The Chocolate World Mini Moulding Line has been specifically designed to attach to your current tempering unit, allowing you to automatically fill several mould layouts during a single production run. The chocolate is distributed directly from the tempering machine, into the moulds, with the ability to fill up to 4 moulds per minute. Surplus chocolate is also collected and pumped back into the automatic tempering machine to minimise any wastage. The Mini Moulding Line is equipped with a vibrating table to eliminate any air bubbles, where the moulds were scraped with a double scraper and vibrated on the vibrating table. Afterwards, the moulds can be turned over in order to create chocolate shells. The Mini Moulding Line features four different heating systems that can be adjusted to your desired setting, is easily moveable on castors and is available in a range of different sizes. You can learn more about the Mini Moulding Line on our website here.

Mixers

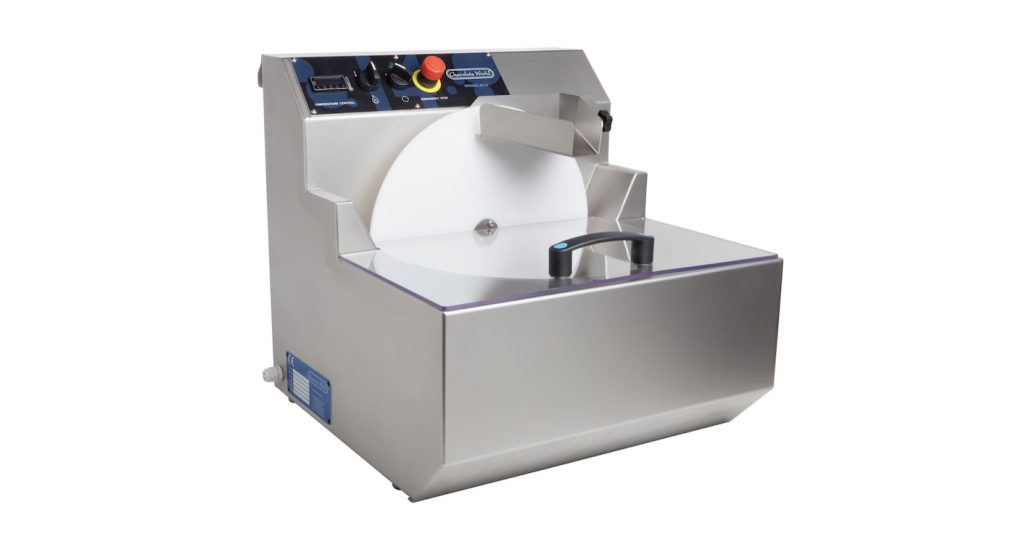

The Escher Premium Spiral Series

The Escher M100 is our best-selling mixer, and for good reason! This fixed bowl spiral dough mixer is designed specifically to improve your production quality and time parameters. The Premium Line was created for intensive use with stiffer doughs whilst featuring the Premium drive system and dual belt resulting in more power being delivered to the spiral tool. The Escher M100 is the most robust spiral mixer on the market, producing the highest quality dough with minimal heat generation to the dough. The M Premium Series has a capacity range from 40kg to 240kg. There are two speeds available for use, automatic timers and a two-way bowl rotation allowing you to reverse the bowl at first speed. You can learn more about the Escher Premium Spiral Series on our website here.

The Tekno Stamap Two Arm Mixer

The Two Arm Mixer by Tekno Stamap is the result of continuous research into the best technology available for both materials and components. Equipped with PED accident-prevention guards and made from thick stainless steel, this mixer is perfect for working with very hydrated and leavened pastry doughs. You can learn more about the Two Arm Mixer by Tekno Stamap on our website here.

Dividing, Rounding & Moulding Machines

Vitella Bun Rounders

The Vitella Bun Rounders have been designed to effortlessly divide and round your dough with accuracy and consistency. Made in Italy, the rounders use an oscillating plate to roll each piece of dough into balls of the correct weight and shape, with a dough weight capacity of 40-135 grams. There are three Rounder models available: Automatic, Semi-Automatic and Manual. Each has the ability to divide and round a variety of dough types, is easy to operate and clean is simple to move around and position with lockable wheels and includes 3-rounding boards. You can learn more about our Vitella Bun Rounder range on our website here.

Sartori SVI Industrial Volumetric Divider Rounder

The Sartori SVI Volumetric Divider Rounder is an automatic divider rounder with a high hourly production rate, giving a precise and high-quality final product with every use. This Divider Rounder perfectly divides and rounds all products, from the soft to very hydrated doughs and can produce up to 6,000 pieces per hour (with a weight range of 15-300 grams), thus dramatically reducing your staff whilst simultaneously improving your product quality. It also has a motorised exit belt with pressure roller, automatic drum oil with a spray system, a user-friendly touch screen panel and hopper flour dusters with an additional flour duster on the exit belt. You can learn more about the CSC Sartori SVI Industrial Volumetric Divider Rounder on our website here.

Merand Atoupain

The Merand Atoupain is a hydraulic, stress-free, dough grid divider designed for complete accuracy and efficiency when working with all types of doughs, whilst also allowing you to use the cold fermentation process. This divider can divide high water content artisan doughs without damage and is equipped with VarioPress® to reduce pressure and keep bubbles inside the dough. There are more than 30 grid models to choose from with the ability to have custom-designed grids made as well. You can learn more about the Merand Autopain on our website here.

Ovens:

The Salva Modular Deck Oven Range

The Salva Modular Deck oven range operates electrically and is recognised worldwide for its baking quality, flexibility and versatility. The range boasts industry-leading features, programs and power-saving qualities to help you bake better. Plus, because the range is modular, you are able to add additional decks in the future if the demand for your products grows. All ovens in this range have guaranteed uniform heat distribution throughout the chamber and the independent modules allow different types of products to be cooked in each module. They are designed in three configurations (2 trays, 3 trays or 6 trays) and are available in 1-5 decks. You can learn more about the Salva Modular Deck Oven range here.

The Salva Elecsol Electric Deck Oven

Salva’s Elecsol Electric Deck Ovens use stone sole plates and adjustable electric heating elements to produce high-quality bread with an outstanding appearance and unrivalled base. This range of ovens is the ideal solution for artisan bakers seeking to make different varieties of quality bread, but with a lighter and more flexible solution than a traditional deck oven. Not only is this oven versatile and easy to use, it’s also convenient, simple to maintain, has low consumption (ensuring that the oven’s heat power is used to the full) and is equipped with a refractory stone of alimentary grade to give a spectacular sole to the final product. You can learn more about the Salva Elecsol Electric Deck Oven here.

The Salva Kwik Co

The Salva Kwik-co Convection Oven range has been designed carefully and consciously with the demands of the modern baker at the forefront of every detail. It is an aesthetically unique oven with excellent baking uniformity and the power-saving qualities that Salva is renowned for. The Kwik-co has a touch screen control panel with a large colour display and programs, even distribution airflow technology with dual speeds and a cool touch double-glazed door. The oven has an eco-friendly design, resulting in energy-saving capabilities and is equipped with the notorious Salvalink technology. With 100 programs, 10 phases, independent heating by program, a built-in library of pictograms and more, this oven is the perfect addition to your bakery. Available in 60x40cm, 75x40cm or 75x46cm tray sizes. You can learn more about the Salva Kwik Co on our website here.

The Venexia San Giorgio Convection Oven Range

The Venexia San Giorgio Convection Oven range is an expression of the most advanced technology, specifically designed to meet the needs of Patisseries, Bakeries and Supermarkets, whilst simplifying work in the kitchen and guaranteeing the highest levels of performance and safety. The oven is available in a range of sizes and configurations, has a WIFI connection for remote monitoring, a high-performance three-phase motor, and a bi-directional reversing fan system with a maximum temperature capacity of 280 degrees. You can learn more about the San Giorgio Venexia Convection Oven range on our website here.

If you have any questions or would like to enquire further about any of the above machines, please don’t hesitate to get in touch with our team of experts. You can also find a range of videos on our Instagram.

Easter is quickly approaching, so if you are in the market for new equipment to assist with your daily production, we highly recommend reaching out as soon as possible.