Categories

- Bakery Equipment 150

- Charcoal Cooking Equipment 7

- Chocolate Machines 27

- Commercial Dishwashers 27

- Commercial Freezers 6

- Commercial Fridges 10

- Commercial Ovens 37

- Depositing & Dropping 10

- Display Cases 18

- Dough Dividing, Rounding & Moulding 16

- Dough Mixer 25

- Gelato Equipment 20

- Ice Cream Machines 27

- Industrial Equipment 34

- Pasta Equipment 15

- Patisserie Equipment 55

- Pizza Equipment 2

- Production Line Equipment 9

- Raw Material, Storage & Milling 4

- Specialty Equipment 19

- Water Chillers and Water Meters 5

- + Show more

Brands

- Agriflex 4

- Bakon 14

- Bernardi 9

- Bertuetti 3

- Bralyx 11

- Bravo 9

- Brx Italia 1

- Canol 2

- Chocolate World 14

- Cleanbake 3

- Comtec 1

- Delfin 4

- E-Mac Professional 15

- Enrich 360 1

- Escher 11

- FirEnace 7

- Fortuna 3

- Four Grand Mere 2

- Gemm 9

- Ifi 21

- IZO 5

- Janssen 1

- Merand 16

- MKN 0

- Mockmill 6

- MyChef 1

- Pavoni Italia 4

- Prisma 0

- Rhima 7

- Rijkaart 4

- Roboqbo 1

- Salva 23

- Sartori 2

- SMEG 29

- Stoppil 5

- Tekno Stamap 15

- Vanrooy Machinery 8

- Venix 16

- Vitella 4

- Watercut 3

- Weber Cooling 1

- + Show more

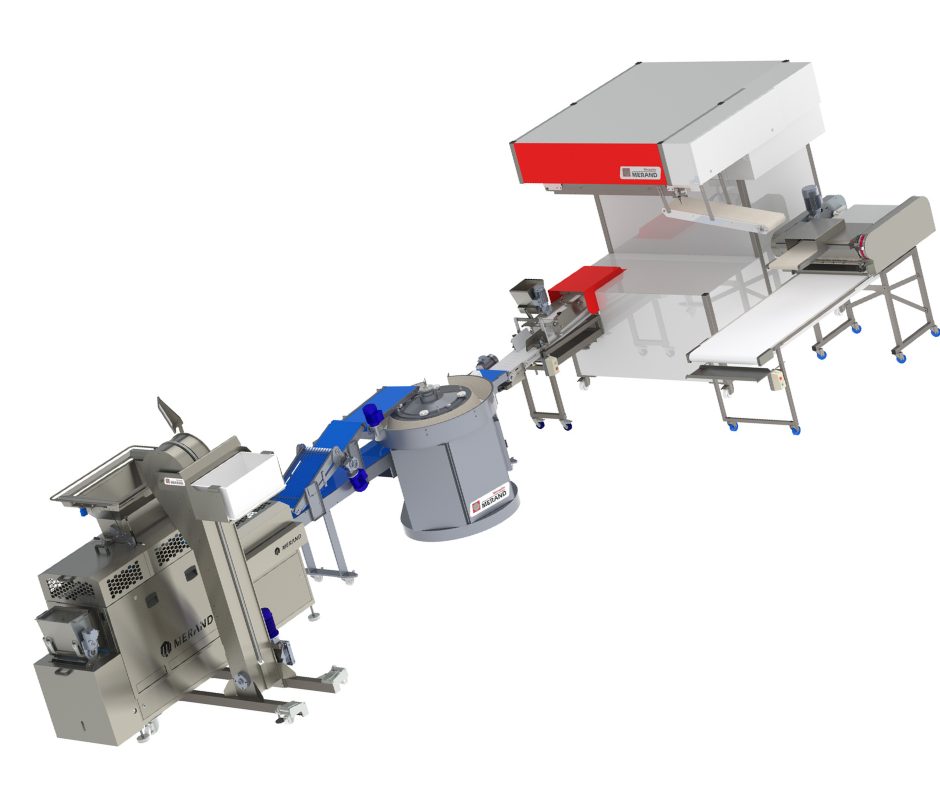

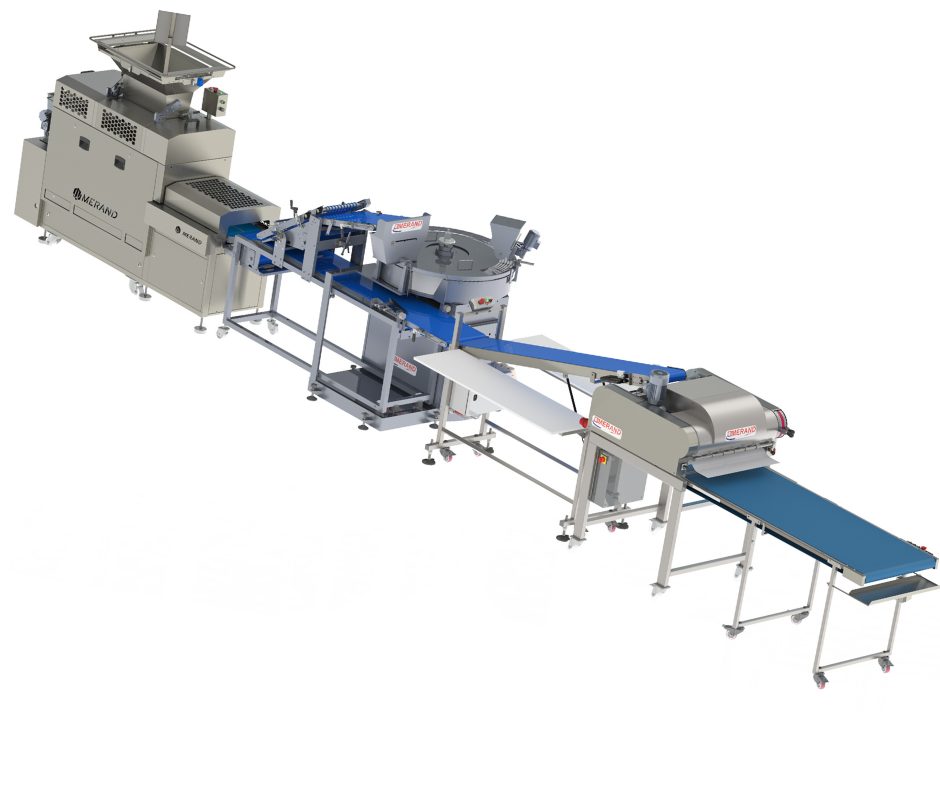

Rheopan Bread Line

Designed as a flexible and customisable stress-free breadline, the Rheopan line has the ability to divide, weigh, seed, mould and round all bread types.

Key Features

- Designed as a flexible and customisable stress-free breadline

- The Rheopan line has the ability to divide, weigh, seed, mould and round all bread types

- Ability to purchase customisable belts to skip processes as required e.g. only dividing and moulding

- All components can be purchased individually

RheoPan® Precision

- Dough ball weighing system and automatic adjustment of the settings ensures a high precision of work

- Specifically crafted for both highly hydrated doughs as well as hard doughs

- There are three models available, with hoppers from approximately 65 to 210kgs of dough

- Capacity of 875kgs of dough per hour (model dependant)

RheoPan® TopSeeds

- An automatic seed dispenser particularly suitable for pieces of dough that have been divided by the RheoPan® Precision

- Equipped with a spraying module to wet the dough before the seed module deposits the seeds

- Includes a water and seeds collecting container, limiting waste and facilitating the cleanliness around the machine

RheoPan® Armor HV

- A horizontal moulder equipped with the Alvéo+® lamination system, which moulds all dough types without stress

- Has an hourly rate of approximately 1,800 dough balls with a rest-time and 2 elongation phases built in

- Highly efficient when combined to the RheoPan® Precision divider

- Heavy duty transmission and stainless steel covers ensure a long lifetime and high volume of daily production

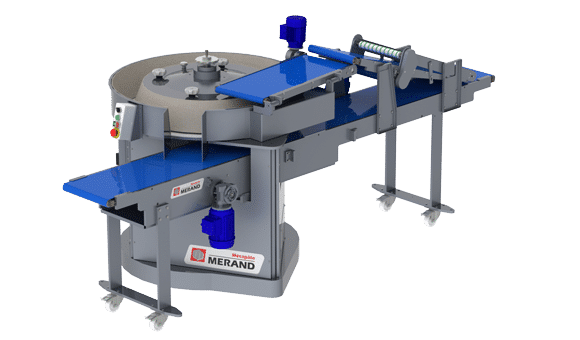

RheoPan® RotaBall

- An eccentric rounder with various settings available to adjust the fitting strength so that the dough balls are rounded without any stress on the dough

- Fits perfectly well with the RheoPan®System thanks to a bypass which ensures that the dough balls don’t need to be rounded and can go straight from the divider into the moulder

- An hourly rate of 1,500 dough balls (for higher rates, a second rounder can be added) and can handle dough ball weights from 200 to 3,000 grams

- Can produce up to 1,800 pieces per hour, model dependant